TFL is using AI to manage Safety Data Sheets

The leather chemicals group decided to use a digital tool to support customers worldwide

Keep reading...

Interview with Matteo and Lorenzo Simoni, at the helm of the Tuscan company specialised in the production of leather finishing plants that has created a new successful division dedicated to robotics

February 2024

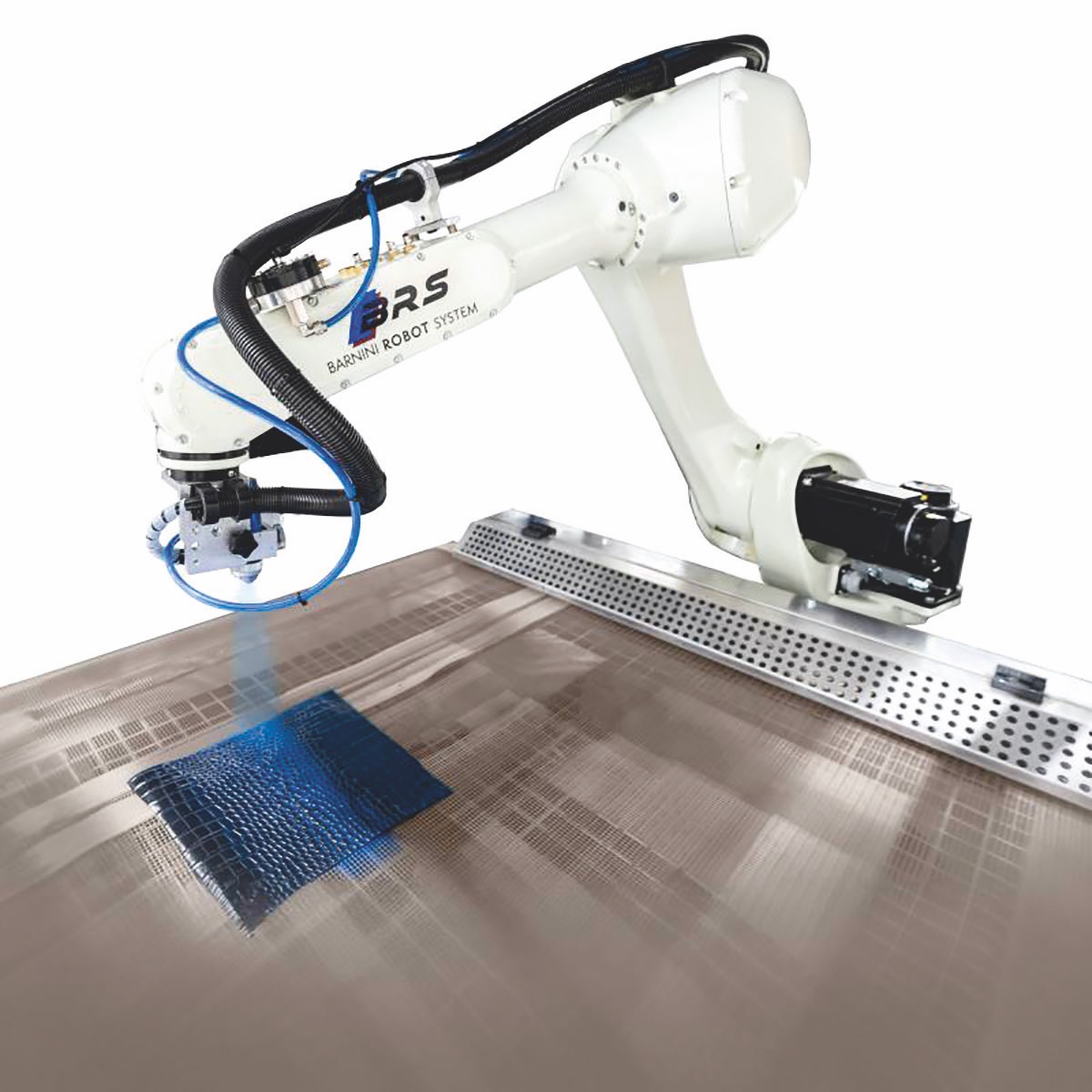

Active since 1965, Barnini srl is an important world reference in the design and construction of leather spraying plants, to which over time presses for ironing and embossing leather have been added through the Mostardini brand acquired many years ago. The most recent branch of activity is robotics, developed through the BRS division ‘Barnini Robot System’. We spoke about this and more at the end of January with brothers Matteo and Lorenzo Simoni, the two young managers at the helm of the mechanical company in Castelfranco di Sotto (Pisa), which has made investment in Research and Development its strong point, aiming to offer its customers tailor-made solutions capable of optimising the leather processing.

You presented your first robots at Tanning Tech 2022, arousing great interest among tanneries. You have come a long way since then…

“We were the first to succeed in getting robots to carry out the operation of loading hides onto machines, undoubtedly a repetitive and onerous operation for workers. We have worked very hard on this project, as proven by the various patents we have filed, and today we are very satisfied with the results obtained so far, both technological and commercial”.

What problems have you encountered?

“The first prototype was born in our R&D laboratory for whole automotive hides. With the experience gained from the first robot, we were able to meet further requirements dictated by the type of leather, its softness and the space available. Today, we are able to handle the various types of leather on both trestle and flatbed. The BRS division has also realised a robotic spraying line called ART for painting leather panels for ready-to-wear fashion. This system allows finishes that are not possible on traditional spraying equipment”.

What kind of tanneries are interested in including robots in the processing cycle?

“There is a lot of interest in the market, especially from tanneries producing automotive leathers where large production runs are normally made. The robots used to load the hides onto the automotive equipment allow two people per machine per shift to be freed, thus offering significant labour savings. For the whole of 2023, we worked exclusively for the Pasubio tannery, which asked to absorb all possible production and where we gained a lot of experience. Now we are opening up to the market”.

Turning to the finishing plants, what’s new?

“We have installed a new, large spraying plant in our in-house workshop. A fully automatic line equipped, of course, with a robot for loading the hides, an automatic product dosing system, an infrared drying tunnel with a continuous rope cleaning system, and finally an automatic stacker. This is a line that requires no personnel to operate, except to programme and set up the work. Next to this system, we will soon be installing a major innovation, which we will talk about later”.

From your point of view, what are the remaining challenges?

“For our part, we aim to further develop automation. It is essential to keep all processing parameters under control in order to guarantee repeatable results. At the same time, we are always listening, because another fundamental issue is the customisation of the plants: every tannery has its own particular requirements depending on the type of product”.

How did 2023 go and how does the new year look?

“2023 went well: we recorded 15% growth compared to 2022 and 50% more than in 2021, and we have orders that cover us for a good part of this year. But there is no shortage of worries for the future, because production in the main Italian districts has slowed down in recent months and there is great uncertainty with regard to international market trends”.

The leather chemicals group decided to use a digital tool to support customers worldwide

Keep reading...

Discover the trend colours proposed by the Italian leather chemicals group

Keep reading...

AICC's weight in the international representative body grows

This content requires a subscription to view. Are you already a subscriber? Sign in