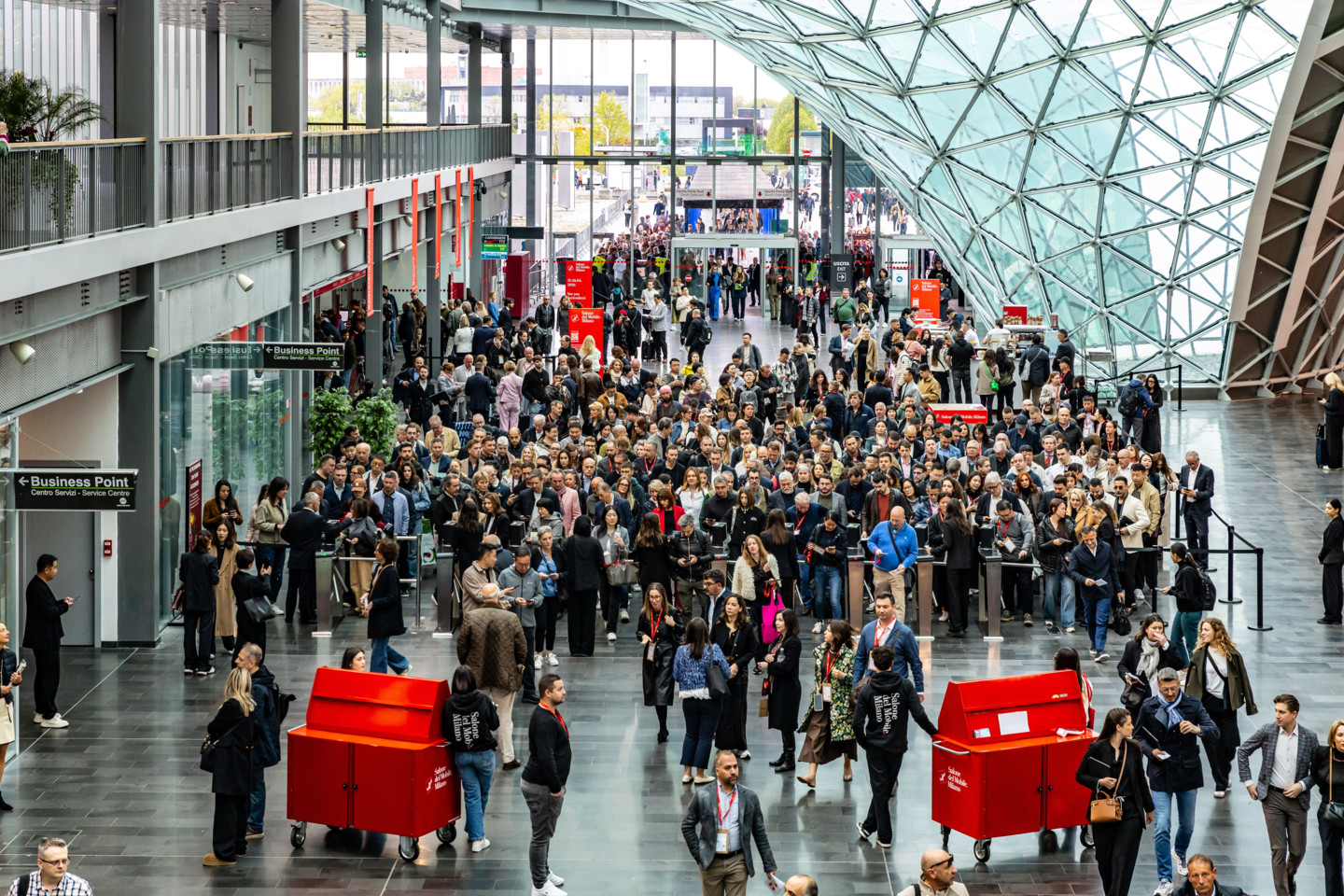

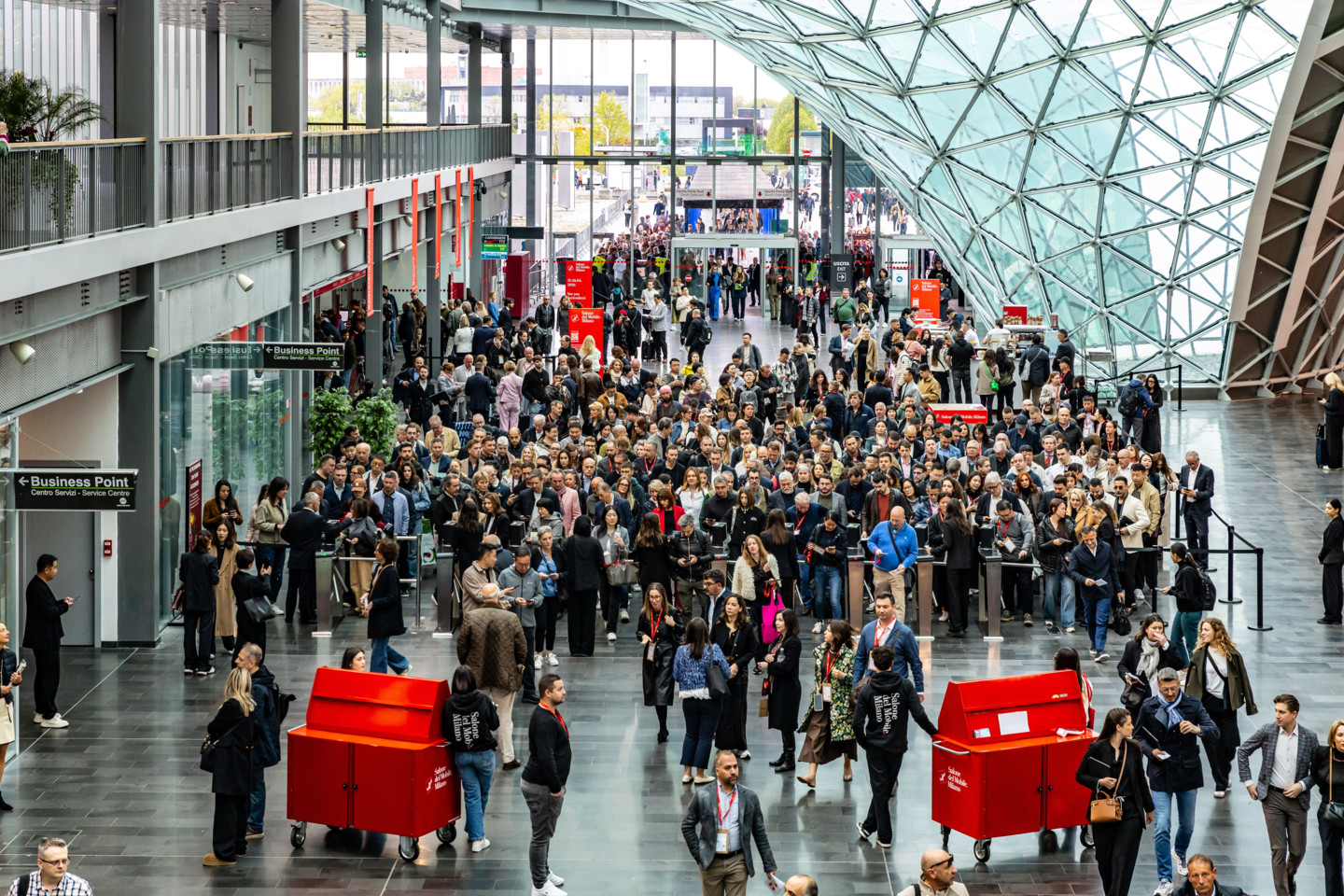

Sold out for the Salone del Mobile

Everything is ready for the big event scheduled from April 21 to 26 with 1,900 exhibitors. Despite the critical issues, the Italian wood-furniture supply chain closed 2025 on a positive note (+1.3%)

Keep reading...

Thanks to technology that uses ultraviolet light to activate the crosslinking process, a brand new range of water-based products has been developed, the result of internal research that began more than two years ago

March 2025

We all know the importance of working in a safe and healthy space. Hazardous substances, such as heavy metals, dusts, gases, fumes, certain chemical agents, are among the main threats to the health of the worker and the surrounding environment. Prolonged or acute exposures to these substances can cause damage to the human body, particularly to the respiratory, nervous and cardiovascular systems. The most common occupational diseases related to these exposures include asthma, chronic lung disease, intoxication and, in extreme cases, cancer. Avoiding the presence of such substances is essential to ensure the safety of employees and the quality of the work environment.

Hazardous Substances in Tannery Finishing Departments

Turning our attention to the environment of the tannery, and in particular to the finishing department, the hazardous substances that can be encountered there are basically solvents, contained in various products, for which alternatives to water have been sought for years, and crosslinking agents, such as mainly polyazyridine and polyisocyanate. What can we do to make the working environment in finishing departments healthier and help preserve the environment around us?

Corichem answers this question with a very concrete solution: SPECTRA

What is SPECTRA?

SPECTRA is a technology that uses ultraviolet light to activate the crosslinking process without the use of catalysts or chemical crosslinking agents.

When special polyurethane polymers developed by Corichem are exposed to certain UV radiation, it induces a reaction that leads to the branching of polymer chains.

This process, which occurs almost instantaneously, even at room temperature, without the need for high heat or the use of solvents, also makes the finishing operation more environmentally friendly and sustainable than traditional methods.

SPECTRA in everyday practice

In everyday practice, SPECTRA translates into a brand new range of waterborne products, the result of in-house research that began more than two years ago.

The products in the SPECTRA range, which are currently under patenting, do not require the use of crosslinking agents, such as polyaziridine and polyisocyanate, and make it possible to obtain leathers with high performance in terms of mechanical strength while preserving their natural appearance and softness.

Benefits of SPECTRA

There are many advantages to be gained by adopting this technology:

– Increased Safety: the absence of hazardous crosslinking chemicals eliminates the risks associated with the handling, manipulation and use of toxic substances.

– Reduced Waste: the SPECTRA crosslinking process generates no product waste for disposal, helping to reduce environmental impact and production costs. Unused product, including that discharged from the application plant at the end of the working cycle, since it does not contain crosslinkers can safely be stored for a long time, waiting to be used at the next processing. Significant is the economic savings, particularly when handling highly fragmented productions.

– Speed and Efficiency: The SPECTRA curing process is extremely rapid, with curing times on the order of a few seconds. This speed allows the desired performance, in terms of physical strength, to be obtained immediately.

– Versatility: the SPECTRA process can be applied to a wide range of polyurethane formulations thus allowing all types of items to be produced.

– Plant Simplicity: introducing SPECTRA in the production process of a tannery is very simple and the usual plants already in use can be used after simple adaptations.

Conclusions

Avoiding the use of hazardous substances in the work environment is not only a matter of immediate safety, but a responsibility to workers’ health and environmental protection.

Investing in this not only reduces risks, but also helps build a stronger corporate culture geared toward collective well-being.

Ultimately, ensuring a safe working environment benefits everyone: employees, the company itself, and the environment in general.

edited by Giuliano Spanevello, CORICHEM finishing department manager

Everything is ready for the big event scheduled from April 21 to 26 with 1,900 exhibitors. Despite the critical issues, the Italian wood-furniture supply chain closed 2025 on a positive note (+1.3%)

Keep reading...

The highlight of the offering presented at the Chennai trade fair will be the “local for local” range of synthetic tannins with extremely low bisphenol content.

Keep reading...

The leather chemicals company aims to lead the evolution of the wet end process

Keep reading...You must login to read this free content

This content requires a subscription to view. Are you already a subscriber? Sign in