ICF and Pro Well join forces to develop new products and dominate the market

Industrie Chimiche Forestali SPA and Pro Well Limited consider strategic collaboration for the global footwear industry.

Keep reading...

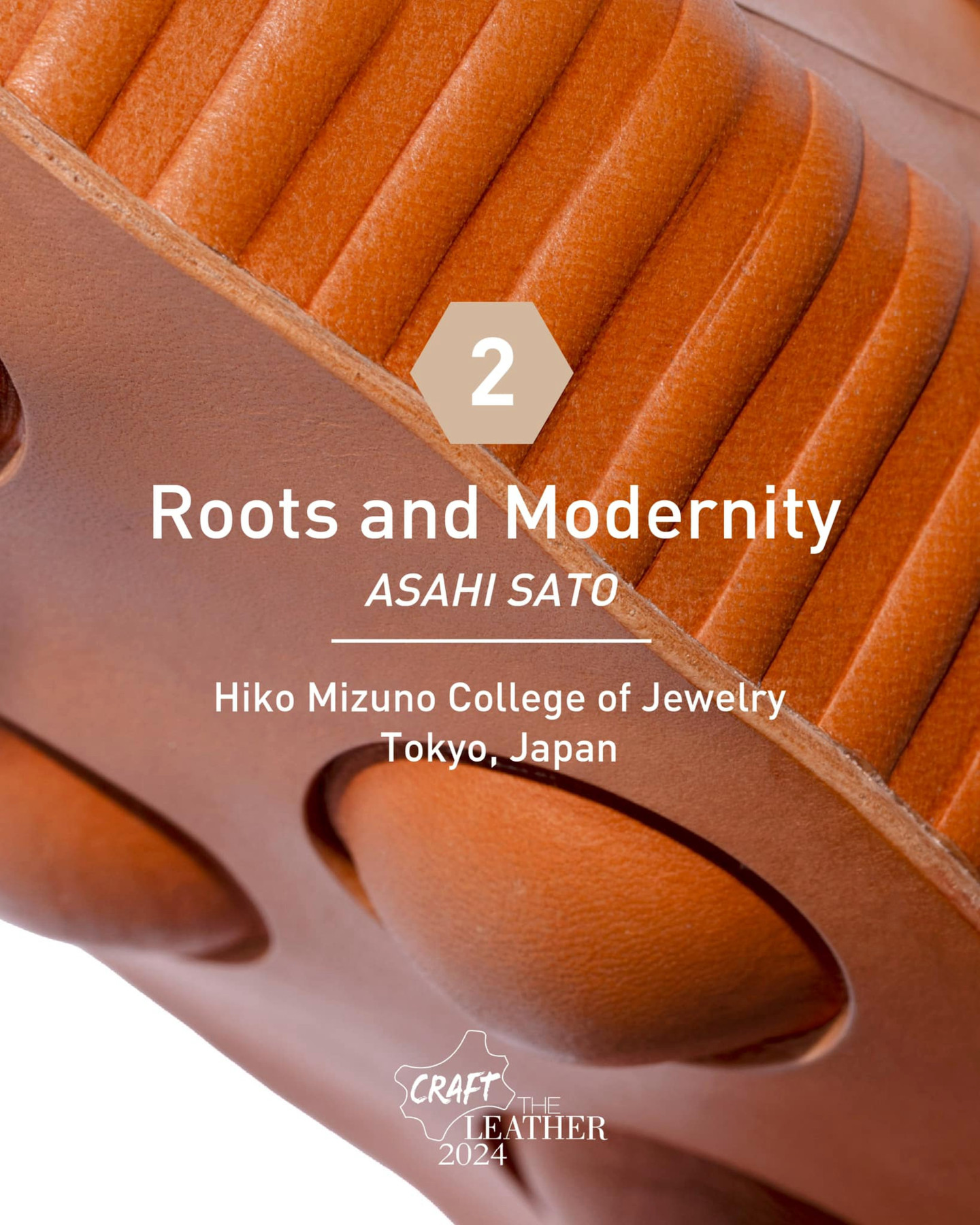

The collection by the designer from the Hiko Mizuno College of Jewelry won the preferences of the technical jury, visitors to Lineapelle and social channels of the Genuine Vegetable Leather Consortium.

April 2025

Japan’s ASAHI SATO is the winner of the 11th edition of ‘Craft the Leather’, the international competition that celebrates vegetable-tanned leather, involving young talents from the world’s most prestigious fashion and design schools: this is the decision decreed thanks to the evaluations expressed by the Technical Jury, the offline votes of the visitors present at Lineapelle and those collected on the Consortium’s social channels. The expert jury evaluated the collections taking into account multiple factors – from technical workmanship to product design and its relevance to eco-design principles.

In his capsule collection of shoes entitled ‘Roots and Modernity’, Sato wanted to emphasise the link between raw material and craftsmanship: with the intention of enhancing the unique characteristics of vegetable-tanned leather, the soles were modelled by working the leather wet, creating organic undulations that give the shoe a distinctive identity. The selection of uppers and lasts was guided by the intention to balance the natural essence of the material with a refined craftsmanship approach and a contemporary aesthetic sensibility.

‘This collection came from my experience in the Craft the Leather workshop held in San Miniato. Witnessing the traditional process of tanning with vegetable extracts allowed me to rediscover the authentic charm of the material. This experience led to the development of new details, such as cutting lines that are intended to recall the texture of wood,’ said Asahi Sato.

Industrie Chimiche Forestali SPA and Pro Well Limited consider strategic collaboration for the global footwear industry.

Keep reading...

Following the success of the first collaboration launched in September 2025, Maison Valentino presents sneakers designed by creative director Alessandro Michele.

Keep reading...

From the sea to the road, always with an unmistakable and timeless style.

Keep reading...You must login to read this free content

This content requires a subscription to view. Are you already a subscriber? Sign in