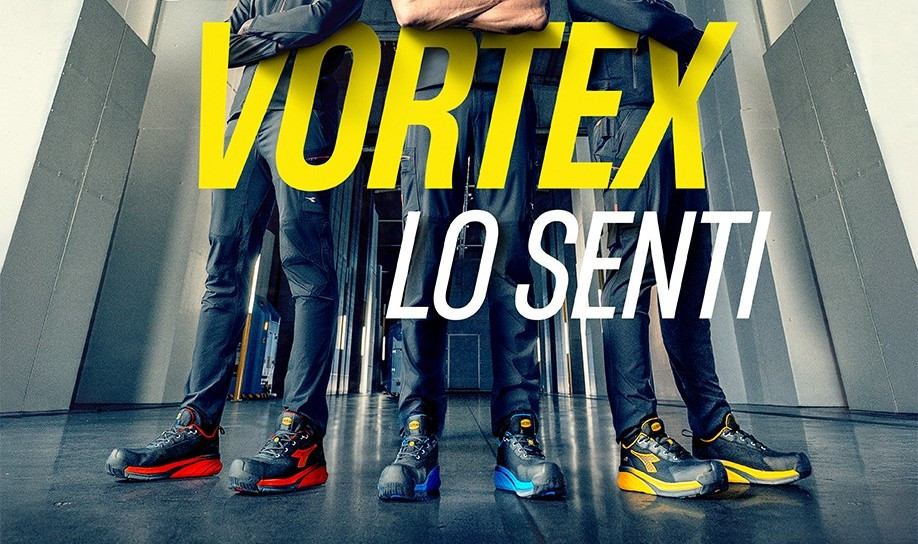

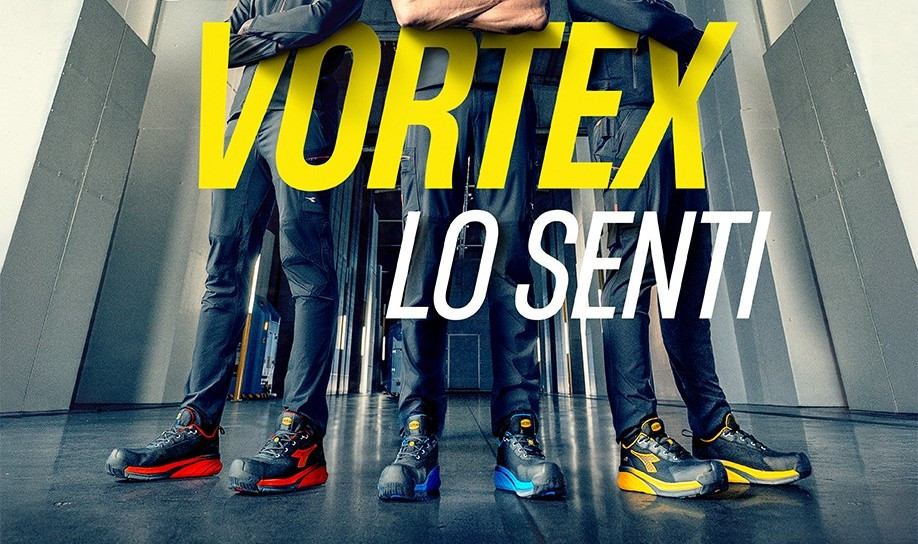

The Utility Diadora Vortex campaign kicks off

Champions Larissa Iapichino and the Ducati Corse team star in the commercial

Keep reading...

Together with the start-up Medere, the Italian brand has developed a service for the creation of customized components that perfectly comply with regulations

September 2025

Did you know that using orthopedic insoles that are not specifically certified together with safety footwear can compromise the validity of the certification as Personal Protective Equipment (PPE)?

The root of the problem: a real need

The growing focus on individual well-being and accident prevention has led to an increased demand for custom orthopedic insoles. In the workplace, however, it is essential that these devices are compatible and certified by the manufacturer for use in safety footwear: only in this way can full compliance with PPE regulations be maintained.

The answer: an integrated and innovative system

Utility Diadora, which has always been at the forefront of research into cutting-edge technologies and materials for workplace safety, has developed a unique service in collaboration with Medere, an Italian start-up specializing in customized medical devices.

Thanks to a free and intuitive web app, partner companies can offer their employees a fast and efficient service for the creation of certified custom-made insoles, directly in the company and without the need for external travel.

Data collection (photos and videos) is just a technical upload phase and is guided, simple, and secure. No health or technical skills are required on the part of the operator performing the scan: the system has been designed to be accessible and compliant for everyone to use.

The data collected is processed by Medere using a customized 3D modeling system, based on the medical prescription. The insoles are manufactured using advanced 3D printing technologies, validated by an orthopedic technician, and delivered directly to the company, accompanied by a Declaration of Conformity.

Utility Diadora and Medere: pioneers working together to set a new standard

The history of Utility Diadora, a leading company in workwear and safety footwear that has always been committed to researching new technologies and materials for the safety sector, combines with that of Medere S.R.L., the Italian start-up that transforms innovative concepts into biomedical engineering products with a focus on finding cutting-edge solutions.

The combination of Utility Diadora’s experience and Medere’s biomedical innovation gives rise to a new paradigm: a fast, practical, and compliant service designed to respond efficiently to the needs of the safety sector, in full compliance with European Regulation (EU) 2017/745 on Medical Devices.

The system allows for significant savings in terms of time and organization, offering an integrated solution that improves worker well-being and optimizes business processes.

Worker well-being always at the center

-Customization and comfort: each insole is designed based on the anatomical shape of the worker’s foot and the activities performed, to improve posture and reduce fatigue and pain (e.g., plantar fasciitis, tendinitis).

-Innovative materials: Medere insoles offer impact absorption, gait stability, and biomechanical support, actively contributing to injury prevention and maintaining musculoskeletal health.

This partnership offers a concrete, technological, and safe solution for creating custom-made insoles certified for use in safety footwear, thus ensuring full validity as PPE. A tangible benefit for workers, companies, and the entire occupational safety ecosystem.

Champions Larissa Iapichino and the Ducati Corse team star in the commercial

Keep reading...

A pop-up installation during Paris Fashion Week celebrates the experience of the leading brand in rubber soles in the industrial sector

Keep reading...

Important recognition for group CEO Claudio Bora at the CEOforLIFE Awards in Rome

Keep reading...You must login to read this free content

This content requires a subscription to view. Are you already a subscriber? Sign in