SUN68: urban identity

For the 2026 AW season, SUN68 confirms its ability to combine functionality, comfort, and contemporary style.

Keep reading...

When the work of the mould maker becomes a training tool for new generations of footwear designers.

December 2025

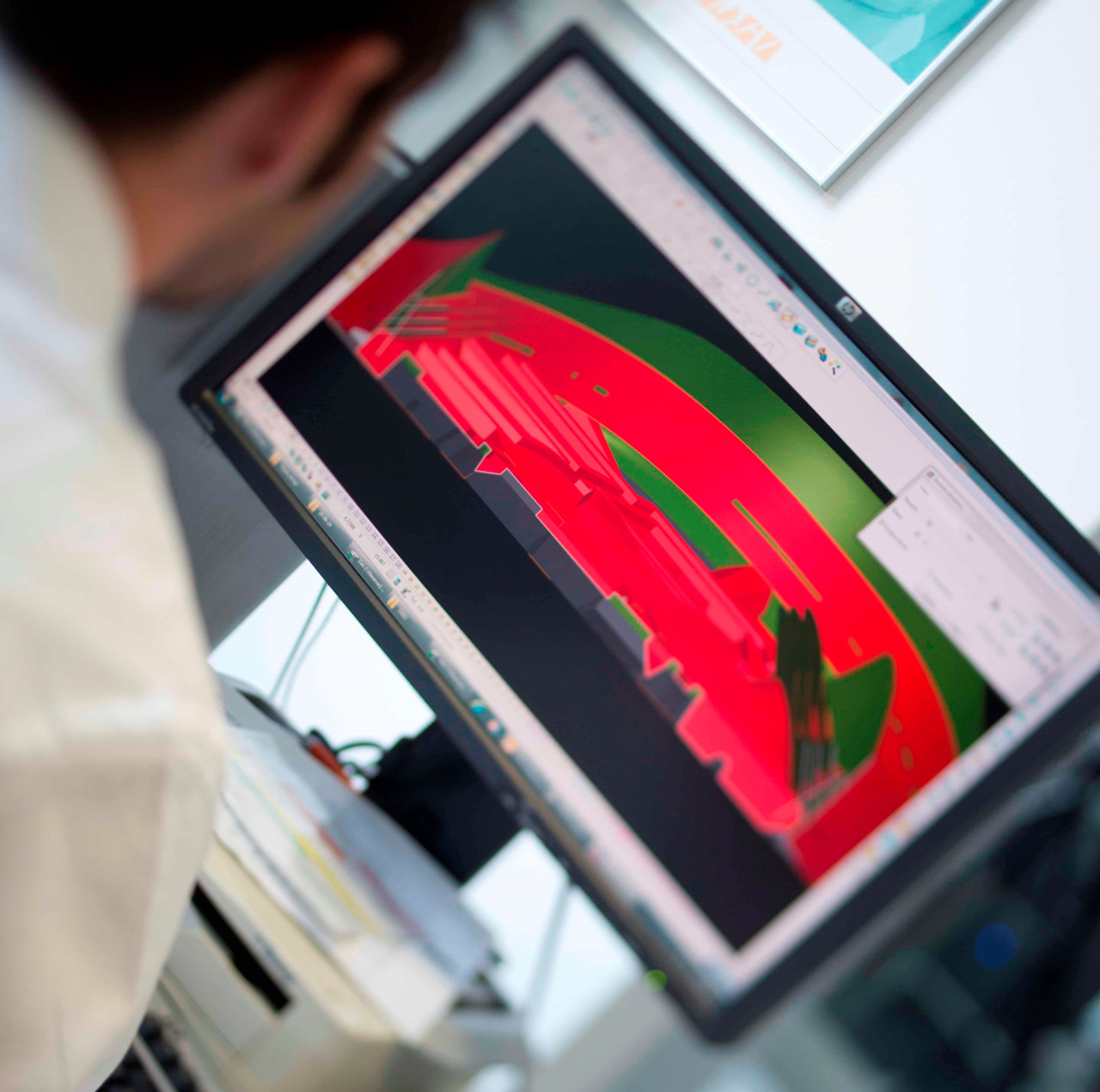

When thinking about the world of injection moulding, it is difficult to associate it with that of design. Mechanics, design, flows and sections; a complex subject, perhaps even a little difficult: it is hard to see the connection with the creativity that characterises a good designer. For the Zago Injection Moulds team, however, nothing could be further from the truth, because, as Marina Zago points out, ‘To make a good shoe, you need good foundations’. It is to support this principle that in 2021 Zago Injection Moulds came up with the idea of creating a series of animated videos for its website (www.zagomolds.com) that clearly and simply describe the injection moulding process for footwear. And it did so for each of the types of moulds that the company produces. Created in 3D graphics in an extremely accurate and incredibly illustrative way, Zago’s videos are able to show and make anyone immediately understand what an injection mould is and what the differences and characteristics of the different types are.

These videos have also recently been used by teachers at the Arsutoria school during training courses for company professionals. ‘The work done by Zago to explain the injection process for the production of soles in a simple but technically accurate way is undoubtedly a valuable resource for all those in the industry who want to better understand what goes on behind the scenes,’ said Matteo Pasca, director of the school. An unexpected opportunity that surprised the company itself: ‘We never imagined that developing these renderings would have such a wide resonance, but we are pleased to know it. At Zago, we have always looked to the future, and today the future of the footwear world is in the hands of the new generations of designers, technicians and craftsmen who, with their passion and dedication, choose to devote themselves to this profession,’ commented Marina Zago.

But who is Zago? Founded in 1958 in S. Angelo di Piove di Sacco, in the Padua area, Zago specialises in the design and construction of moulds for polyurethane and rubber injection. In the industry, Zago is synonymous with excellence, reliability and attention to detail, traits that make it a valued partner across the entire spectrum of production, from the most classic single and two-colour designs to the most complex, ambitious and pioneering multi-density designs using the latest generation of materials.

For the 2026 AW season, SUN68 confirms its ability to combine functionality, comfort, and contemporary style.

Keep reading...

The Spanish brand stands out for accessories capable of blending functionality and elegance, for the young generation always on the move.

Keep reading...

Co-founded by James Barshall, Charles Finch and Captain Nat Lemieux, Equipement De Vie is the sporty-chic footwear brand for sailing enthusiasts and beyond.

Keep reading...You must login to read this free content

This content requires a subscription to view. Are you already a subscriber? Sign in