Valentino Garavani/Vans: Cruise Collection 2026

Following the success of the first collaboration launched in September 2025, Maison Valentino presents sneakers designed by creative director Alessandro Michele.

Keep reading...

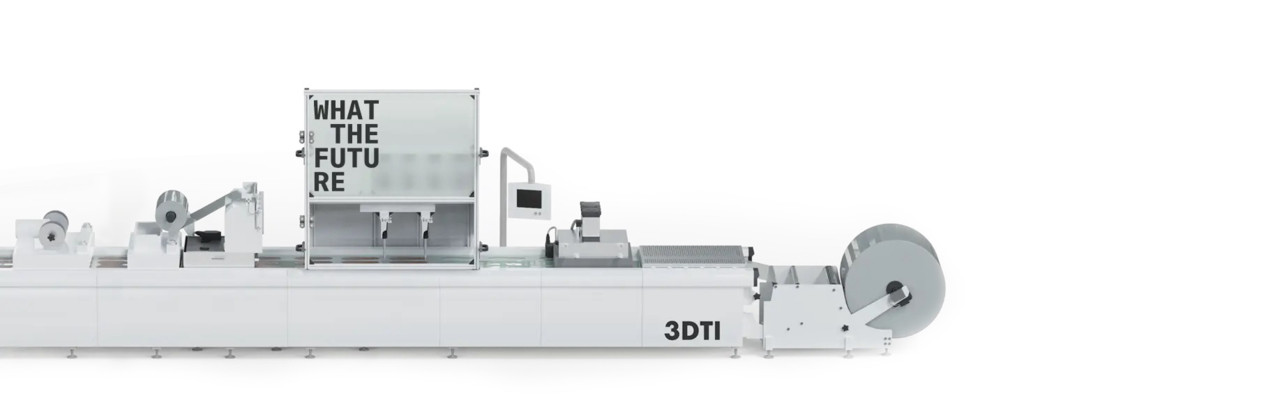

A technology that combines 3D printing, thermoforming and injection moulding is revolutionising footwear production, offering flexibility, sustainability and reduced costs thanks to an innovative approach.

December 2025

In the heart of a warehouse in Amsterdam, among machinery under construction and prototypes that change shape from one day to the next, a completely new way of making footwear has been born. This is where What the Future is rewriting the rules of industrial production, proving that sustainability, efficiency and flexibility are not just slogans, but concrete processes. Their 3DTI technology – a unique combination of 3D printing, thermoforming and injection moulding – promises to transform an industry often hamstrung by costs, lead times and rigid supply chains. A future shaped not in months, but in hours.

What the Future develops batch-to-mass manufacturing technologies that enable local, fast and low-impact production. Thanks to low-cost, reusable and recyclable 3D moulds, set-up times are drastically reduced, while the possibility of using bio-based materials and almost zero-waste processes could represent a leap forward for the entire industry. Not only that, but by adopting direct injection onto the upper, the company reduces costs by up to 20% and overcomes the limitations that have held back large-scale sustainable production.

Leading this revolution is Carrie Howe, Managing Director & CEO, as well as a former Olympic sailor, with a clear vision: to overturn a production system that produces too much, too far away and with too many compromises for the planet. We met her during the event organised by APICCAPS, “Welcome to the industry of the future!”.

Where does the urgency to reinvent manufacturing come from?

«The industry is in crisis because it can produce millions of identical pieces, but it is unable to easily switch from a prototype to customised production, from small series to large volumes. Above all, it generates too much waste. It was clear to us that a new approach was needed.»

What is the real innovation of your technology?

«We have combined existing technologies — 3D printing, thermoforming, automation and injection — to enable factories to produce in a cleaner, faster and more flexible way. Our 3DTI uses inexpensive and recyclable 3D moulds, reduces lead times from months to hours and allows us to work with more sustainable materials, such as bio-based ones.»

Can we go into more detail?

«3D printing: our technology uses low-cost 3D-printed moulds instead of traditional CNC-milled aluminium/steel moulds. As a result, production start-up is reduced from months to hours. This enables rapid and cost-effective development of new products and drastically reduces time-to-market.

Thanks to the use of 3D-printed moulds, shapes can be quickly modified on 3DTI production lines. The combination with upper injection allows for the same-day production of multiple products at a lower cost than existing mass production processes.

Thermoforming: our patented technology transforms standard thermoforming machines into flexible, high-speed production lines, thanks to the use of low-cost, 3D-printed, air-cooled moulds. After production, the moulds are shredded, pelletised and used to create filaments for new moulds.

Injection moulding: 3DTI offers many possibilities and a variety of applications. It can process any liquid, paste or gel. From complete shoes to individual parts (insoles, midsoles, outsoles, etc.), footwear made with 3DTI is tested to industry standards and designed to have minimal environmental impact.»

How do you differ from traditional technologies?

«We offer an end-to-end solution, designed for existing factories that do not have the space or margins to take risks. With us, they can innovate without disrupting everything. And the cost reduction exceeds €5 per pair: we are talking about a real impact.»

You are also working on the sustainability of materials. What does that mean in practice?

«For us, it is not an extra: it is the starting point. We use recycled plastic moulds that are turned into new filament at the end of their life; we work with natural rubber in liquid form, which reduces waste and impact; we eliminate glue by injecting directly onto the upper. Less chemicals, fewer steps, fewer emissions.»

I understand that at your headquarters in Amsterdam, you never stop experimenting…

«That’s right. This is demonstrated by the fact that at the heart of What The Future is a team of designers, engineers and material enthusiasts intent on doing things that many consider impossible, such as transforming a food packaging machine into a shoe factory. Not just any machine, but one designed to produce plastic containers for ham sold in supermarkets. Today, that machine does something much more interesting. It produces trainers. Printed in one night, not months.»

Can you give us a concrete example of the benefits of the systems you build?

«The traditional footwear industry is rigid and expensive. Steel moulds, aluminium tools, large-scale production and delivery times measured in months. Want to make a prototype of a new sole? Left and right, in all sizes? It will cost you at least €200,000.

With our technology, the same mould costs €15 in materials and is 3D printed overnight using recycled ABS. Instead of carving moulds out of metal, our system thermoforms plastic sheets. As I said, it’s a technique borrowed from the world of packaging, using heat and pressure. Then, it combines them with 3D-printed inserts for total flexibility. One day it’s children’s shoes, the next day it’s street style for adults, without making any changes to the tools, no waste, no delays, just a smooth and easily adaptable process.

Our modular system also allows us to change moulds quickly, enabling us to test different solutions or move into production, something that traditional industry can hardly imagine.»

Shall we talk about materials?

«Our soles are made from liquid latex. Pure, natural rubber extracted directly from trees grown in forests rich in biodiversity, not in monocultures. The liquid is poured into a mould to which a minimum amount of vulcanising agent is added during injection to cross-link the polymer chains and transform the rubber from a sticky material into a resistant elastomer. It is then mixed with natural additives to meet the industry’s requirements in terms of abrasion, slip resistance, etc.»

What is your vision for the future of footwear?

«A local, modular, easily repairable production system, where brands can produce close to their target market without relying on huge, distant supply chains. Our first plant in Mississippi will produce up to five million pairs a year: proof that this model is scalable.»

Following the success of the first collaboration launched in September 2025, Maison Valentino presents sneakers designed by creative director Alessandro Michele.

Keep reading...

From the sea to the road, always with an unmistakable and timeless style.

Keep reading...

For the 2026 AW season, SUN68 confirms its ability to combine functionality, comfort, and contemporary style.

Keep reading...You must login to read this free content

This content requires a subscription to view. Are you already a subscriber? Sign in