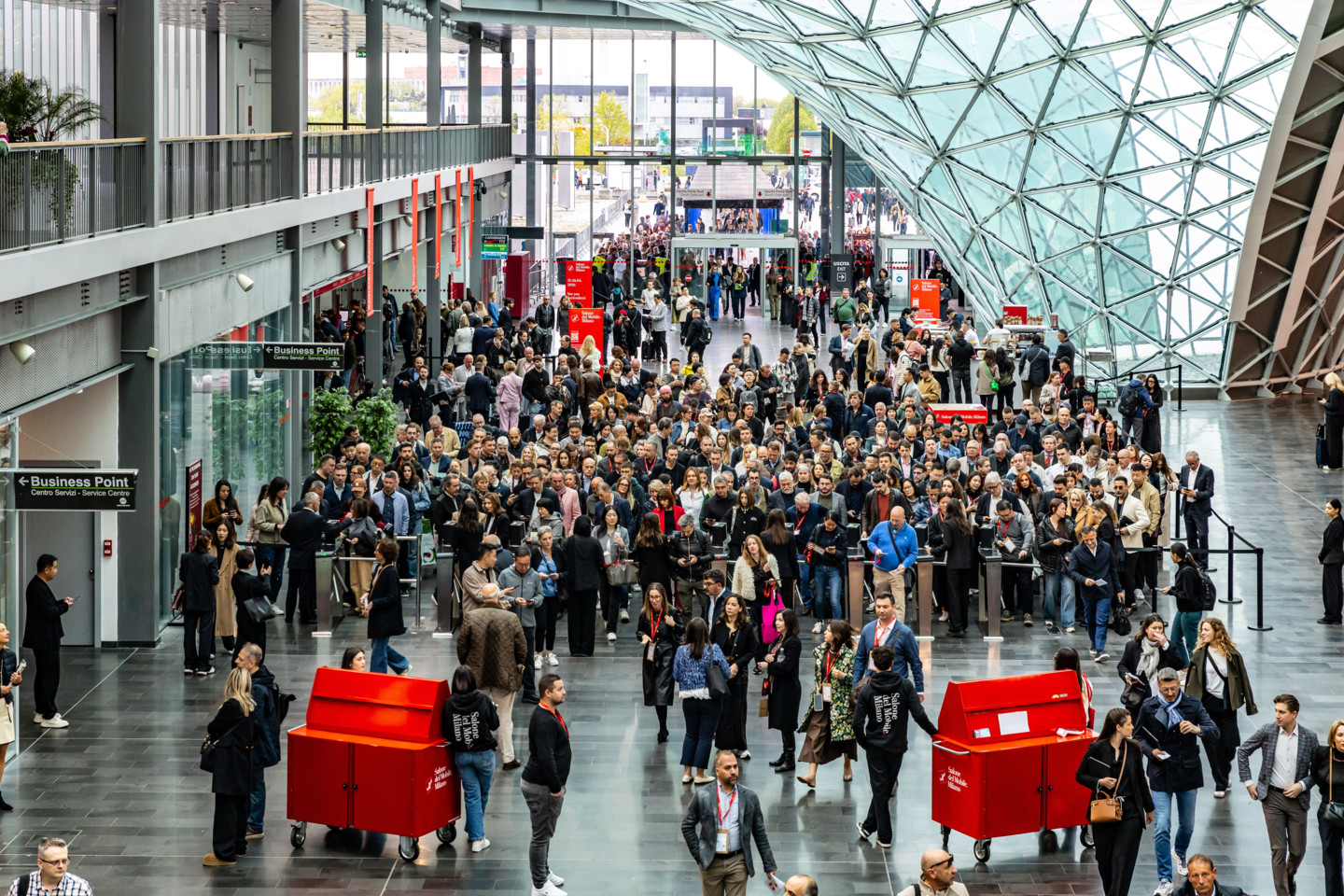

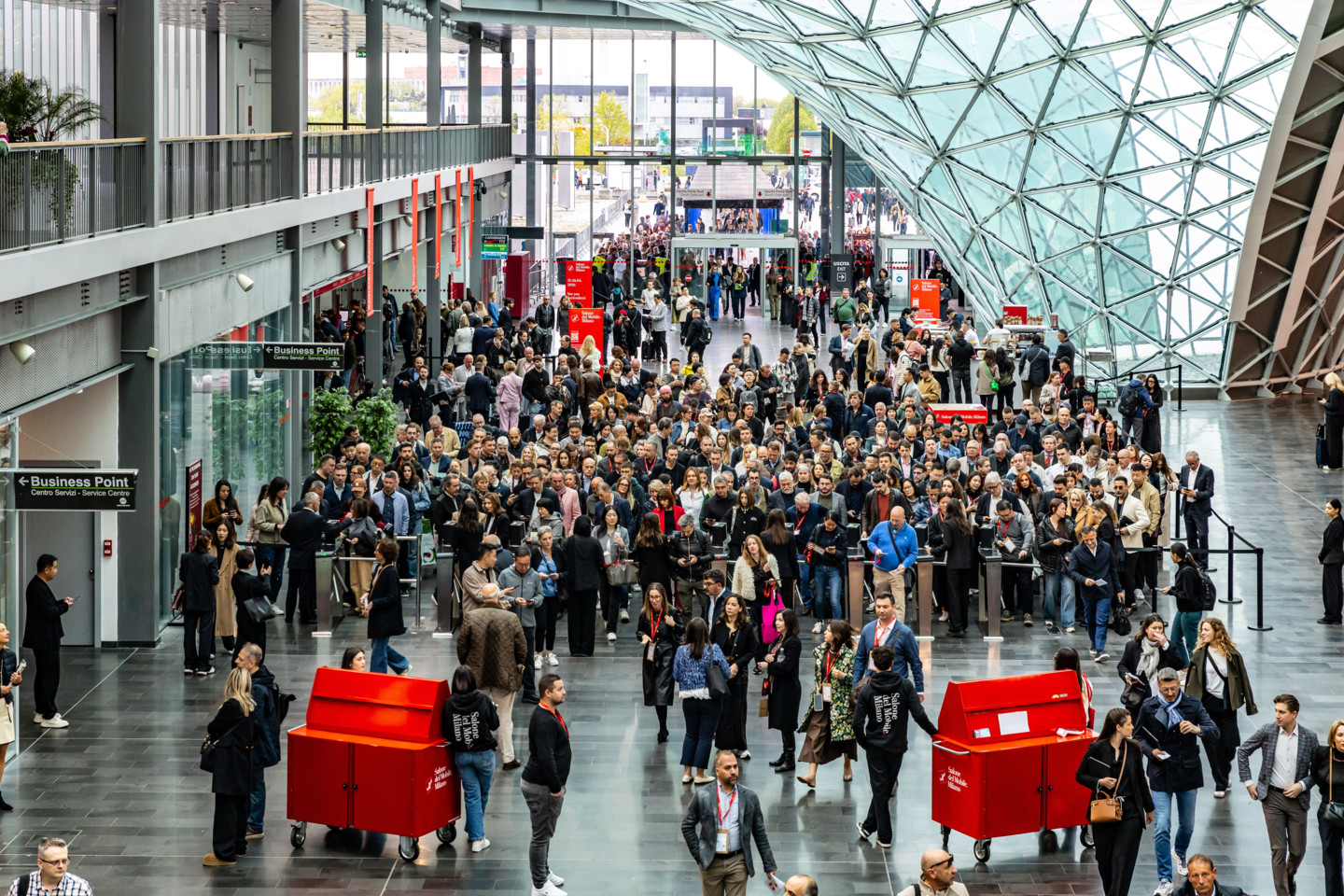

Sold out for the Salone del Mobile

Everything is ready for the big event scheduled from April 21 to 26 with 1,900 exhibitors. Despite the critical issues, the Italian wood-furniture supply chain closed 2025 on a positive note (+1.3%)

Keep reading...

The project, which also features Silvateam, is revolutionizing the world of tanning and offering the industry an increasingly sustainable way to provide leather as a high-quality material for brand products.

July 2025

“The basic idea, which originated from Japan’s great manufacturing and engineering tradition, is that the product is the most eloquent manifestation, the most concrete interface between materials engineering and industrial processes and the world of consumption. It is the starting point for all conversation about sustainable innovation. Innovation has always started with the product, and the sustainable revolution will start with the product.”

This is how Professor Alessandro Bruni of the University of Pisa sums up the essence of the Life I’m-Tan project, presented on July 17 in Vinci (Florence) after four years of research and development. The event was much more than a simple presentation of results: it was a manifesto for the future of vegetable-tanned leather. A future in which sustainability, performance, and industrial scalability are not antagonists.

A hundred-year-old chestnut tree and a piece of leather: two symbols of the tanning tradition that have been speaking to each other for centuries but which, thanks to science, can now finally truly understand each other. The LIFE I’m-Tan project – an acronym for “Innovative Modified Tannins” – has demonstrated that nature, when supported by technology and industrial vision, can compete with the most high-performance chemical solutions while keeping its green soul intact.

The project – funded by the European Union with € 1.2 million out of a total budget of € 2.3 million – involved several partners: Crossing, a spin-off of Ca’ Foscari University in Venice, developed the chemistry of the processes; CRCF designed and managed the pilot plant; Conceria INCAS tested industrial production; while the Aquarno Consortium analyzed the environmental impact of wastewater.

The result: the development of a new generation of chemically modified natural tannins (CMNT) that promise to change the rules of the game in leather tanning.

TANNINS, BUT SMARTER

The project, which started in September 2021 and, as mentioned, is funded by the European Union under the LIFE program (LIFE20 ENV/IT/000759), had a clear objective: to improve vegetable tanning and retanning processes through a new generation of chemically modified natural tannins (CMNT) derived from chestnut and quebracho.

At the heart of the innovation is a two-stage process, as explained by Andrea Cassani, BU Innovation Manager at Silvateam: “First, the natural extracts are purified, then chemically modified according to the principles of green chemistry. The result? More reactive, more stable, and higher-performing tannins. They are able to bind better to the collagen in the leather, reduce the organic load in wastewater, and guarantee a much wider color palette than traditional vegetable tannins.”

For those in the industry, this is no small feat. The limitations of vegetable tanning – the impact of wastewater, the stiffness of the leather, and its poor compatibility with products such as sneakers and car interiors – have always been the Achilles’ heel of a technology perceived as noble but obsolete.

FROM THEORY TO THE FACTORY: CONCRETE RESULTS

LIFE I’m-Tan has not remained a laboratory exercise. The project has seen the creation of a pilot plant capable of producing hundreds of kilograms of CMNT per week and the industrial-scale prototyping of five leather items, now ready for use in footwear and leather goods collections: Parma, Corvara, Water, Kendo MF, and Oxide. All tested on 2,500 raw hides from New Zealand and processed by INCAS tannery machinery.

The mechanical and chemical tests speak for themselves: CMNT-treated hides offer superior performance to traditional vegetable alternatives and, in some cases, even come close to chrome-tanned hides. Above all, however, they significantly reduce environmental impact. The environmental impact results of LIFE l’m-Tan leathers are excellent, showing significantly lower values than the benchmarks, with reductions in Global Warming Potential (GWP) of between 6% and 25%. Tanning operations such as pickling, tanning, and post-tanning are strongly influenced by the use of chemicals. The type and quantity of substances used play a crucial role in determining the environmental profile of the final product.

In the case of leather footwear on synthetic-chrome hybrid, all LCA impact categories show significant reductions, ranging from 20% to 78% compared to the benchmark. The effect of chemical consumption, a parameter used to calculate GWP, has been reduced by 36%.

CLEANER WATER, CLEANER LEATHER

One of the critical issues for every tannery is wastewater management. LIFE I’m-Tan has monitored key parameters by comparing traditional tanning baths with CMNT-based ones. The results are encouraging: the new tannins reduce COD by up to 19% and significantly improve biodegradability.

The combined strategy is also interesting: CMNT1, with a high concentration, is more effective in terms of fixation and chemical load reduction; CMNT2, which is lighter, offers greater color flexibility and superior biodegradability. The synergy between the two allows for an optimal balance between aesthetics, performance, and environmental impact.

CIRCULAR ECONOMY: FROM BY-PRODUCTS TO ADDED VALUE

The scientific soundness of the project is also evident in the words of Gustavo Defeo, Scientific Director of CTC ARS Tinctoria: “The concept of Good Leather should allow us to leave no trace in terms of production waste, creating versatile leather articles with different end-of-life options and promoting eco-design-oriented material choices. The figures for I’m-Tan tannins are moving in this direction.”

One of the most interesting insights of the project was the valorization of waste: both that generated in the production of tannins and that derived from leather scraps. Ongoing tests show that these materials can be converted into organic fertilizers or other high-value products, with a view to achieving concrete circularity, not just declared.

As proof of this, Life Cycle Costing (LCC) has shown that, for a small surcharge (30-40 cents/kg), CMNTs reduce overall costs thanks to lower dosages, simplified treatments, and more efficient wastewater management.

TOWARDS INDUSTRY: IS THE SUPPLY CHAIN READY?

The Vinci event was not just a scientific celebration. Above all, it was a forum for discussion between players in the supply chain: from chemical companies to tanneries, from industry associations to major fashion and design brands.

Francesco Sapienza, Sustainable Materials & Data Manager at Kering, confirmed the group’s interest in sustainable alternatives: “We are redesigning our business to continue to stimulate and increase sustainability in the future, while contributing to the transformation of the luxury sector and doing our part to overcome the important social and environmental challenges of our generation.” He continued: “Since 2019, we have been working towards an increasingly sustainable supply chain and are committed to fundamental research into the evolution of materials for an increasingly sustainable impact.”

Poltrona Frau also confirms its sustainability-oriented strategy linked to leather. Daniele Gardini, R&D Leather Manager, explains: “We will never abandon leather, which is sustainable by nature and, thanks to its qualities, ensures the durability of our products (another sustainable aspect). As a company, we have decided to continuously optimize our production processes to reduce our environmental impact. This will be our focus over the next 5 years. Leather will always remain the Prince of our materials.“

From the world of footwear, Paolo Bruno, Strategic Advisor at Garsport, offers a critical but optimistic perspective: “Today, brands that understand the drive and opportunity for differentiation that a sustainable business model can give them in the market can truly think about educating the end consumer. And that is exactly what is needed. It is brands that must offer sustainable products to their customers and, in doing so, lead them towards more conscious consumption.”

To try to sum up: the market is ready, but bold decisions are needed. Sustainability – if real, measurable, and scalable – is no longer a cost but a competitive advantage.

CONSUMER PERCEPTION: EDUCATING ABOUT SUSTAINABILITY

The Social LCA analysis conducted as part of the project revealed interesting aspects of consumer perception. Sixty-six percent of participants consider sustainability important or very important in their purchasing decisions, and many say they are willing to pay up to 10% more for ethical and environmentally friendly products.

However, there is still a knowledge gap about the environmental benefits of leather, which requires more effective and transparent communication strategies from brands.

AND NOW?

Now that the project is complete, here is a possible roadmap. The CMNT process has been engineered to achieve industrial production of 1,700 tons per year. Activities will be extended to the three main Italian tanning districts (Arzignano, Santa Croce, Solofra) with the aim of making the technology replicable and transferable to other European tanneries.

But that’s not all: CMNTs are already showing potential applications in sectors such as agriculture, animal nutrition, food & beverage… A silent but radical revolution, starting from a chestnut forest and ending up in a luxury car or biodegradable packaging.

THE FUTURE? IT’S ALREADY HERE.

True sustainability is not made up of proclamations, but of data, processes, and industrial choices. LIFE I’m-Tan has shown that it is possible to innovate without sacrificing the identity of leather. That it is possible to go beyond the rhetoric of “natural” to build high-performance, clean, and replicable solutions.

As Fulvia Bacchi of UNIC and Lineapelle pointed out during the event: “Tanning is by definition a circular industry. But today it is no longer enough to be recyclers, we must be pioneers.”

Everything is ready for the big event scheduled from April 21 to 26 with 1,900 exhibitors. Despite the critical issues, the Italian wood-furniture supply chain closed 2025 on a positive note (+1.3%)

Keep reading...

The highlight of the offering presented at the Chennai trade fair will be the “local for local” range of synthetic tannins with extremely low bisphenol content.

Keep reading...

The leather chemicals company aims to lead the evolution of the wet end process

Keep reading...You must login to read this free content

This content requires a subscription to view. Are you already a subscriber? Sign in