New OrthoLite factory in Vietnam

Located in the northern region of the country, it will catalyse production and support for the local market.

Keep reading...

The exclusively European production (20% in the Netherlands and the rest in Portugal) with Italian materials tells of a great attention to quality and detail. The world awaits Floris Van Bommel.

March 2025

“The moment has arrived! So far, we have invested heavily not only in our home market of the Netherlands, but also in our core markets of Germany, Austria, Switzerland, Belgium and Luxembourg. Now we are ready to take the next big step and collaborate with international partners”, said Pepijn van Bommel.

That is why the brand took part in the MICAM in February and says it is willing to continue on this path. The shoe factory, founded in 1718, is now run by the ninth generation of the family and holds the title of supplier to the Dutch Royal Court. For decades it has been the leading shoe manufacturer in the Netherlands, with a total annual turnover of EUR 60 million in 2024. It is the only shoe factory left in the Netherlands and employs around 150 people.

“We have been fortunate to record steady and continuous growth over the past decade. In particular, thanks to our online business, which has allowed us to compensate very well for market fluctuations caused by Covid and the many shop closures,’ says Pepijn van Bommel. E-commerce has gone hand in hand with other successful strategies such as the opening of several company-owned shops (12 storefronts) and cooperation with major players in wholesale distribution. And now, on the strength of its position, the brand is ready to position itself internationally by focusing on stable partnerships with strong retailers, distributors and agents.

“Our advantage is to be able to offer a fully developed collection for men and women, segmented between luxury and mainstream. A democratic luxury characterised by originality and quality, always at affordable prices.”

Located in the northern region of the country, it will catalyse production and support for the local market.

Keep reading...

The brand has transformed its family tradition into a sustainable vision, creating footwear that does not use leather or animal-derived materials, but rather recycled fabrics and recovered resources.

Keep reading...

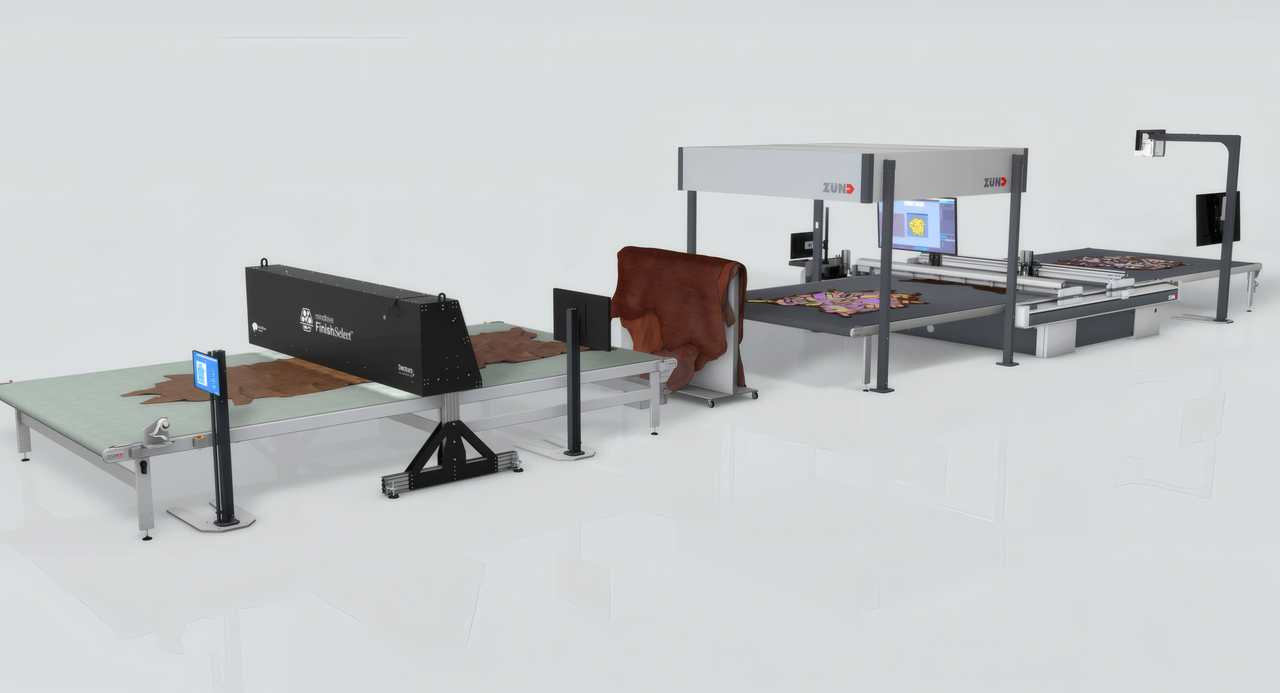

The Swiss company, together with Mind and Mindhive Global, presented the Dectura workflow at Simac, a fully integrated solution for precise and efficient leather cutting.

Keep reading...You must login to read this free content

This content requires a subscription to view. Are you already a subscriber? Sign in